Queris APS

Queris APS

Awaken the dormant power of production!

Queris APS is a complete Advanced Production Scheduling implementation package consisting of 2 components:

Consultation, analysis and configuration service of your production scheduling process.

Opcenter Advanced Planning and Scheduling solution (formerly Preactor) provided and developed by Siemens.

The APS system is a tool with which you can improve not only the efficiency of production planning, but also the course of the entire production process, its efficiency, raw material rotation, and increase sales.

24%

48%

53%

49%

The APS system is an advanced tool for automatic planning and scheduling of production orders in real time. The design and functionality of this type of IT tool (as well as its integration with other IT solutions in the company) allows complex calculations to be performed in a short period of time, resulting in the generation of optimal production plans according to pre-defined assumptions.

Calculations based on simple and complex algorithms can be used, for example, to create optimal production schedules according to various criteria:

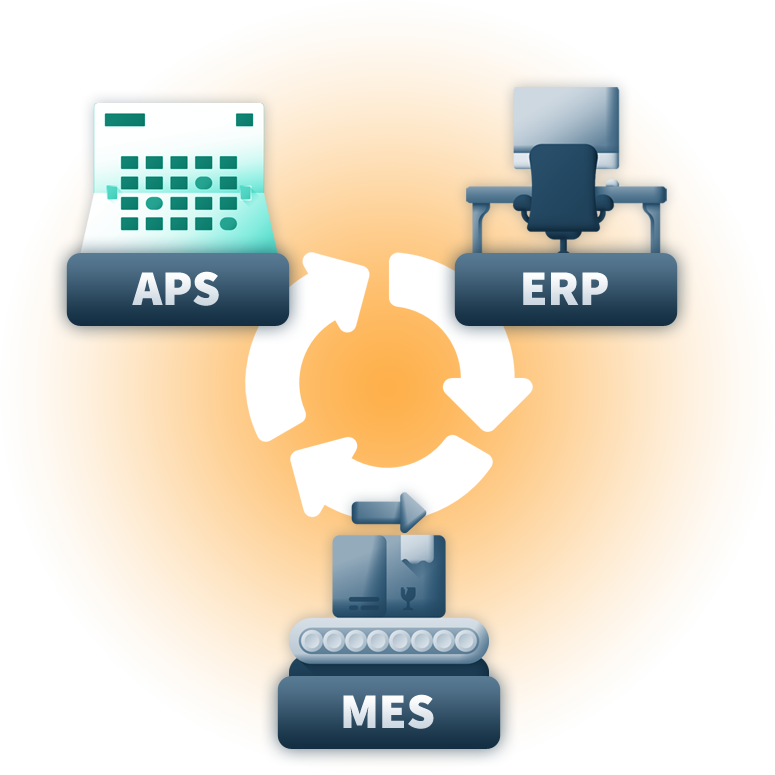

The lack of ERP or the absence of an MES system prevents the correct implementation of advanced production planning software.

If you want to create optimal production schedules, you need to get them right.

We can help you take control of the entire scheduling process and teach you how to use the APS system.

Production planning optimization is one of the two key components of the Queris APS package. During the audit, we will examine your production process and suggest how you can generate the most cost-effective production plans.

Here are the key aspects of scheduling optimization that will help you answer the question: How do you schedule production?

A modern system for advanced production scheduling – Opcenter APS (formerly Preactor). A solution with which you automate schedules and set optimal production plans.

Select planning criteria, enter production orders and control the execution of the plan. You will integrate Opcenter APS solution with your ERP system, MES system and CMMS system to achieve even better results.

System APS to nie tylko automatycznie generowane harmonogramy. Poznaj inne benefity, które osiągniesz dzięki nowoczesnemu planowaniu produkcji.

Choose more than just the APS system itself. With an audit of your planning process and complete system configuration according to your production environment, you will fully optimize your results.

With optimal production plans, you will use the maximum of your production capacity.

Better production plans will allow you to fulfill customer orders faster, putting you ahead of the competition.

Production scheduling will help you reduce changeovers and the associated downtime and costs.

The advanced production planning system will allow you to plan over a long time horizon, making it easier to predict results.

Automated scheduling reduces the workload of planners and enables faster creation of optimal production queues.

The APS system shows you the optimal inventory of raw materials, reducing the cost of excess inventory.

A production planning audit provides you with comprehensive information about all key processes, production resources and constraints.

Integrate APS with MES to gain total control over production schedules and ongoing work in progress.

Learn about the advanced production planning system and see how it works in practice.

APS systems are an extension and complement to programs such as ERP or MES. Using data such as the number of orders, production rates, or machine availability, the system is able to present simulations of different production situations. The planner can then choose the best schedule that best suits the current needs.

Advanced production scheduling programs make it possible to monitor the progress of the plan in real time and to react immediately to disruptions (breakdowns, changes in priorities, or changes in the ordered quantity of assortments).

With APS systems, companies gain greater flexibility and the ability to respond more quickly to change. This translates directly into:

See the full capabilities of the APS Opcenter system and how it can be implemented.

+48 505 953 172

+48 512 390 381

+48 508 308 723

Increased production efficiency with modern solutions

Increased production efficiency with modern solutions